How We Can Reduce Sulfur From Iron Ore

Mining and Extraction: Oxide Ores

Crushed ore in the leach pad. The pregnant leach pond is in the distance. The crushed ore rests on a leakproof membrane to protect the underlying ground and prevent the acid and copper ions polluting the local water table. 2. Dilute sulfuric acid is poured over the crushed ore using an irrigation system. (Courtesy of Red Tiger Mining Inc.)

Energy and Environmental Profile of the Mining Industry 4

sulfur, sodium, potassium (alkalis), alumina, silica and sometimes titanium. ... There are a variety of beneficiation methods that can be used to prepare iron ores, depending on ... The crushing stages will reduce the iron ore from several feet in diameter at the primary stage to six inches down to .

Distribution Of Key Natural Resources Across The World ...

· You can reduce the amount of waste you create by choosing what rubbish you throw away. ... South Africa is also a major iron ore producing country of the African continent and ranks 8th in the world iron ore production. ... Sulfur in crude oil can corrode .

Mineral Resources: Formation, Mining, Environmental Impact ...

Processing metallic ore (, gold, silver, iron, copper, zinc, nickel, and lead) can involve numerous steps including crushing, grinding with water, physically separating the ore minerals from nonore minerals often by density, and chemically separating the metal from the ore minerals using methods such as smelting (heating the ore minerals with different chemicals to extract the metal) and ...

Sulphur technology, removal and recovery – Worley

We are everything sulphur. As the largest sulphur recovery and gas treating technology provider, we work with refineries, gas plants, coal gasifiion, power, and chemical plants around the world. With our colleagues at Chemetics® and JESA, we cover all parts of the sulphur chain. We remove sulphur from fossil fuels. We recover it as ...

3 Ways to Remove Iron from Well Water

· Besides hardness, high iron levels in water is the most common problem well owners deal with. With the right water filter, however, you can remove iron from your well water quickly and easily. Some filters, like water softeners, are ideal...

Extraction of Metals from Concentrated Ore: Reduction of ...

After concentration of ores, we must now extract metal from in it. This step will give us metal in its pure form the native form of metal. First, we must convert the ore to a suitable form. The metals need to be in an oxide form for the reduction process to be easier. Hence the ores are converted to oxides, so it is ideal for reduction.

purifiion of copper by electrolysis metal extraction reduction of ores .

How to extract copper from ores? How do we purify impure copper by electrolysis carbon reduction of copper oxides, sulfides carbonates are described. How can we purify copper by electrolysis? The electrolytic purifiion of the impure copper is described with the electrode equations. Scroll down for revision notes on extraction procedures and theory which should prove useful for school ...

Why can iron not be extracted by the electrolysis?

Answer: Actually the extraction of a metal from its its ore depends upon the selection of a proper reducing is a moderately active metal and its oxides can be reduced using carbon and not by using electrolysis. On the basis of energy considerations iron can easily be reduced using cok...

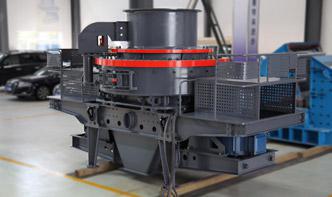

removing sulfur content in iron ore

removing sulfur content in iron ore. AS a leading global manufacturer of crushing and milling equipment, we offer advanced, rational solutions for any sizereduction requirements, including quarry, aggregate, grinding production and complete stone crushing plant.

Ironmaking 101 – From Ore to Iron with Blast Furnaces | .

· Roasting or calcination of the ore oxidizes some of the sulfur, phosphorus and arsenic impurities. Sulfur oxide is volatile and evaporates off or is washed out. Iron is mainly extracted from hematite (Fe 2 O 3) and magnetite ores. Natural or direct shipping iron ores contain between 5070% iron and can be fed directly into the blast furnace.

Pig Iron Manufacturing Process

· In his discussion of electricfurnace production of pig iron and pig steel before the Engineers' Society of Western Pennsylvania, Dr. J. W. Richards defines pig steel as "a metal with per cent, or less of carbon, a very small amount of silicon and manganese, low in sulphur and phosphorus, and made directly from iron ore in the electric pig iron furnace."

Reduction swelling behaviour of iron ore pellets

reduction swelling behaviour of olivine and acid iron ore pellets under simulated blast furnace shaft conditions, ISIJ International, Vol. 52, No. 7, pp. .

how to remove sulfur and copper from iron ore

How We Can Reduce Sulfur From Iron Ore . How To Remove Sulfur And Copper From Iron Ore. How to flush iron residue from pvc pipes jul 02, 2016way eaiser to do the same thing municipalities do and open or remove a valve at a lower end of the system then let the water run at fullo around the house at lower taps and open them individually or in pairs, whatever keeps the flow velocity in the pipes ...

Different Types of Iron Ore

· Impurities in Iron Ores. There are certain impurities that lower the value of iron ores or may even make them valueless. Sulphur in the ore goes partly into the iron and steel and makes them brittle. While it is possible by roasting the ore and by other means to remove the sulphur, the presence of any considerable amount is objectionable.

ENERGY TRANSITION: Decarbonizing shipping tougher than tackling sulfur.

· Brazilian iron ore exports down 10% in September. Oct 5, 2021 21:55 ... That's because ship owners could switch to fuels with lower levels of sulfur or use an exhaust gas cleaning system known as a ... we can prepare a quote for you and show you around. Get Started. Contact Us +44 (0) 20 7779 8260. fastmarkets ...

What Do We Really Know about the Role of Microorganisms in ...

We summarize the evidence that links sulfurmetabolizing microorganisms and sulfide minerals in nature ... Keywords: iron sulfide mineral, biomineralization, pyrite, mackinawite, greigite, microbial sulfate reduction, microbial sulfur disproportionation, sulfatereducing ... sulfur and iron can be immobilized in the form of iron sulfide ...

Characteristics and adaptability of iron and sulfur ...

· Suzuki I, Takeuchi TL, Yuthasastrakosol TD, Oh JK: Ferrous iron and sulfur oxidation and ferric iron reduction activities of Thiobacillus ferroxidans are affected by growth on ferrous iron, sulfur, or a sulfidic ore. Appl Environ Microbiol. 1990, 56: .

How to Get Rid of Sulfur When Well Water Smells (2021 Guide)

· The problem with sulfur bacteria, aside from being unsafe to drink, is that it can encourage the growth of slimy, thick iron bacteria. This iron bacteria can clog plumbing fixtures and pipes and affect water flow. Sulfur in the water even corrodes metals such as iron and steel.

Sulfurreducing bacteria

Sulfurreducing bacteria are microorganisms able to reduce elemental sulfur (S 0) to hydrogen sulfide (H 2 S). These microbes use inorganic sulfur compounds as electron acceptors to sustain several activities such as respiration, conserving energy and growth, in absence of oxygen. The final product or these processes, sulfide, has a considerable influence on the chemistry of the environment ...

Latest Posts

- تستخدم كسارات ثانوية

- مصنع مطحنة المطرقة في الأردن

- محطم 250 TONNS الألمانية تكلفة تصميم

- تستخدم محطم ملموسة

- التلال تكسير الحجارة تركيب آلات

- كسارة الفحم ومصنع الشاشة

- صيانة العمودية مطحنة

- آلة طحن الكرة المصغرة

- كسارة الحجر تأثير آلة الكسارة

- أسعار معمل تكسير الحجارة في الجزائر

- كسارات خرسانة مستعملة للبيع في المملكة المتحدة

- مصنع الاسمنت chettinad في كارناتاكا

- شاشة تهتز عالية الكفاءة

- كسارة محجر الجرانيت الإمارات العربية المتحدة

- كسارات الخرسانة مفيد

- Crusher Spare Parts Allis Chalmers 54x

- Finland Stone Crushers Used In Cape Verde

- What Store Is Distributor Of Products In The Philippines

- Metal Iron Ore Crushing Machine Process

- Industrial Extraction Of Aluminium From Bauxite

- Tools For Marble And Granite In China

- Cement Plant Single Line Diagram

- Tecalemit Sbm 650 Price

- Paver Block Making Process Project Report

- Make Cement Grinding Mill From China

- Rock Crusher Cone For Sale Spokane

- Mobile Jaw Crusher Plant Series

- Used Gold Mining Equipment Manufacturer Malaysia

- Mica Ore Processing In Canada

- Construction Machine Equipment Raipur