Manufacture Process Of Ball Mill In Spain

Investigating the effect of production process of ball ...

Summary Chocolate compound was produced using ball mill refiner, and the effect of agitator shaft speed and refining time on the physical quality parameters (particle size, colour and steadystate rheology) of compound chocolate was determined using response surface methodology. The shaft speed and refining time range were selected between 40–60 and 10–30 min, respectively.

The Scalability of Wet Ball Milling for The Production of ...

Results: Comparable particle sizes of about 151 nm to 190 nm were obtained for both active pharmaceutical ingredients at the same milling time and milling speed when the drugs were processed at 10 g using low energy wet ball milling or 120 g using high energy wet ball milling in batch mode, respectively. However, an adjustment of the milling ...

cement plant equipments manufacturer and suppliers of ...

Ball Mill Manufacturers: As a leading turnkey cement plant manufacturer, we design and supply ball mills for cement industry. We expertise in heavy fabriion with largest workshops in Delhi NCR in India with all latest equipped and technologies required for cement plants for up to 3000 TPD production.

Grinding balls manufacturing process Melting, Molding and ...

The grinding ball is a grinding medium used in ball mill and material used in grinding mills, widely used in metallurgical mines, cement building materials, thermal power generation, flue gas desulfurization, magnetic materials, chemical industry, coal water slurry, pellet, slag, ultrafine powder, fly ash, calcium carbonate, quartz sand, and other industries ball mill.

What does Ball Mill Do?

26/08/2021 · The ball mill has the characteristics of high production efficiency, environmental protection, low grinding cost, continuous production, and wet and dry grinding of different raw materials. Ball milling mode. Ball mills can be divided into dry ball mills and wet ball mills according to different working methods.

Manufacture Process Of Ball Mill In Spai

Manufacture Process Of Ball Mill In Spai. Manufacture Process Of Ball Mill In Spai. Every ball passes through exacting inspections that automatically detect and remove offspec balls A significant number of random samples is tested for hardness and examined microscopically for structure and finish

manufacture process of ball mill

manufacture process of ball mill. There are forty years of manufacturing history, with three major production bases,over 160 senior RD engineers and 600+ large and mediumsized digital processing equipment, The firstline technicians and professional aftersales service personnel up to 2,300+ and 200+ advanced technology and craftsmanship, adopting international ...

Chapter 17. Processing of Metal Powders

1 Chapter 17. Processing of Metal Powders Introduction This chapter describes the powder metallurgy (P/M) process, in which metal powders are compacted into desired and often complex shapes and sintered (heated without melting) to form a solid piece. This process first was used by the Egyptians in about 3000 to iron tools. One of its first

mineral processing production line has three machines

breakage process of mineral processing comminution. 1. Introduction. Nowadays, with the increasing depletion of high grade and coarsegrained ores, the trend is towards the extraction of lowgrade ores .This can have two consequences for themineralsindustry; first to process larger tonnages ofmineralraw material and second to grind the raw materials to finer sizes, which in turn leads to ...

Ball Milling

Ball milling is a way to exfoliate graphite using lateral force, as opposed to the Scotch Tape or soniion that mainly use normal force. Ball mills, like the three roll machine, are a common occurrence in industry, for the production of fine particles. During the ball milling process, there are two factors that contribute to the exfoliation.

Investigating the effect of production process of ball ...

29/12/2016 · Chocolate compound was produced using ball mill refiner, and the effect of agitator shaft speed and refining time on the physical quality parameters (particle size, colour and steadystate rheology) of compound chocolate was determined using response surface methodology.

Investigating the effect of production process of ball ...

At ball mill processing, crystalline lactose resulted in significantly lower viscosity, for example 15% at 40 s−1; thus, for this process, it can be recommended to use special milk powders high ...

(PDF) On the Use of Ball Milling for the Production of ...

22/04/2015 · In the present research work, the mixture of boron carbide and graphite ceramic powders with a theoretical composition of 50 % each by. weight were mechanically alloyed in a laboratory ball mill ...

Classifying and Ball Mill Production Line

The production line adopts internationally popular batch continuous production process: ball mill and classifier system. Including crushing, grinding, classifying, packaging, magnetic separation, conveying, lifting, etc. After the ball mill, classifiers can be connected in parallel or in series to simultaneously produce products with multiple ...

Ball Mills

13/02/2017 · In all ore dressing and milling Operations, including flotation, cyanidation, gravity concentration, and amalgamation, the Working Principle is to crush and grind, often with rob mill ball mills, the ore in order to liberate the minerals. In the chemical and process industries, grinding is an important step in preparing raw materials for subsequent treatment.

Ball Mill Parameter Selection Calculation

30/08/2019 · 1 Calculation of ball mill capacity. The production capacity of the ball mill is determined by the amount of material required to be ground, and it must have a certain margin when designing and selecting. There are many factors affecting the production capacity of the ball mill, in addition to the nature of the material (grain size, hardness, density, temperature and humidity), the degree of ...

Industrial Ball Mills: Steel Ball Mills and Lined Ball ...

Steel Ball Mills Lined Ball Mills. Particle size reduction of materials in a ball mill with the presence of metallic balls or other media dates back to the late 1800's. The basic construction of a ball mill is a cylindrical container with journals at its axis. The cylinder is filled with grinding media (ceramic or .

Ss production in overflow ball mill

The last stages of vibrating screening is 12 mm D80=de to 10 mm measured by exploitation team The ball mill size added: 2/3 is of 100mm and 75 mm 1/3 Actually the initial work index changed and we tried to calculate the operational work index according to a followup of the parameters below but I don't have any conclusions according to this ...

Classifying and Ball Mill Production Line

Advantages of Solid Waste Processing by Classifying and Ball Mill Production Line Fly ash can be ground and separatedgrade ash, ultrafine ash, specific surface area m²/kg; Fly ash can be separated and extracted from 245μm ultrafine beads, which can be used as rubber and plastic fillers instead of calcium carbonate;

Comparative study of SPEX and planetary milling methods ...

be effective in the ball milling process [9]. The aim of the present study is to investigate the ball milling types (Planetary ball mill and SPEX mill) and finding impacts of ball milling speed for the production of γAl 12Mg 17 nanosized particles. 2. Experimental procedure Al 12Mg 17 nanoparticle preparation: The Al 12Mg 17 intermetal

Latest Posts

- قطع غيار آلة طحن جوز الهند

- تشغيل معدات تكسير وغربلة الفحم

- طلب مصنع كسارة الحجر

- الصينية شاشة كسارة متنقلة في برمودا

- صناعة الاسمنت السوداني

- تعدين الحجر الجيري 325 شبكة

- كسارة الحجر الدولوميت سعر الجهاز في مصر

- الطوب المحمول المصنعة محطم في الجزائر

- المصنعة طاحونة الحمص في إسرائيل

- كسارة صخور صغيرة مصر السعر

- حجم مطحنة الاسمنت

- شركة تعدين الرصاص والزيك

- كيف صغيرة يمكن أن تكسير تأثير الصخور كسر

- مصنعي مطحنة الأسطوانة العمودية

- رمل السيليكا صنع آلات

- Lebanon Market Cost Savings Mobile Jaw Crusher Station

- Product Single Size Aggregate Quarry Malaysia

- Coal Mining Editbau Ite

- Diamonds Processing Machinery Diamonds Plant

- Mesin Pemecah Batu Mini Por Le

- Coal Mining Joint Venture In Indonesia

- Mining Project Metal

- Hammer Crusher Building

- China Top Mining Equipment

- Fine Stone Crusher Powder

- Powder Filler China

- Posho Mills Shunning

- Cement Grinding Plant Layout

- Kerala Building Materials M Sand

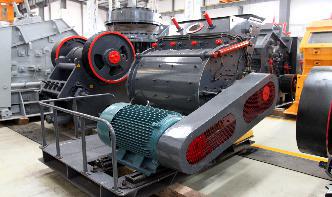

- Ball Mill Image Side And Frant