Process To E Tract Copper From Fine Concentrate Powder

Summary of Gold Extraction Process

Aug 22, 2019 · 1. Flotation Gold Extraction Process Principle. Flotation gold extraction process is based on the difference of physical and chemical properties of the ore surface, and is processed by flotation reagent to make the useful mineral adhere to the bubble to achieve the purpose of gold extraction.. Gold is an easyfloating mineral, so flotation gold extraction process has always been .

Copper Concentrate

Some of the typical processes include the extraction of metals from various types of iron ore to hot metal and from hot metal to steel, from copper concentrates to pure copper, and from aluminium scrap to pure aluminium or its alloys. These processes are generally complied due its multiphase, high temperature, and highly reactive nature.

Copper Mining and Extraction Sulfide Ores

Place these products in the extraction process in ascending order of copper content. Use the flow chart as a guide: Matte Ore Cathode copper Blister Anode copper Copper concentrate Fire refined copper; Use a periodic table to find the atomic masses of the elements in cuprite and chalcocite. Then work out the percentage of copper in each mineral.

Novel Method for Comprehensive Processing of LowGrade ...

Low grade copper concentrate, composed mainly of plagioclase, quartz, pyrite, chlorite, chalcopyrite, glauconite, is a promising source for the future recovery of copper and other valuable components which processing by existing methods is not economical. An alkali fusionleaching method followed by acid leaching for extraction of copper, aluminum, silica, iron and silver from such lowgrade ...

Process To Extract Copper From Fine Concentrate Powder

belgian process for extraction of zinc. 2 Zinc can be produced by a process called froth flotation, which is also used for reduction of copper and lead or This process involves grinding the zinc ore to a fine powder, mixing it with water, pine oil, and flotation chemicals, and then agitating the mixture to "float" the zinc to the surface...

Electrowinning Copper Chemistry Tutorial

Electrowinning can be used to extract the copper from these copper oxide ores. The process for extracting copper from copper oxide ores can be summarized as: Mining : digging or blasting to obtain the ore from the surrounding rock. Crushing : mined ore is crushed into very small pieces. Grinding : crushed ore is ground into a powder ...

cobalt processing | Uses, Supply, Facts | Britannica

Cobalt processing, preparation of the metal for use in various products. Magnetic alloys form the most important use of cobalt. The second most important cobalt outlet is in the making of hightemperature alloys, in which it improves the hightemperature strength and corrosion resistance.

CNA

The invention discloses a method to prepare copper sulphate by copper concentrate, adding built additive to the copper concentrate powder, to make the iron in the copper concentrate and the additive form a basic iron sulphate double salt deposit difficult to dissolve in dilute sulphuric acid solution, when leaching copper sulphate of copper calcining, the deposit is eliminated with the residue ...

Copper Flotation

16/05/2016 · Although basic porphyry copper flotation and metallurgy has remained virtually the same for many years, the processing equipment as well as design of the mills has continually been improved to increase production while reducing operating and maintenance costs. Also, considerable attention is paid to automatic sensing devices and automatic controls in order to assure maximum metallurgy and ...

Cyanide Gold Extraction Process

Dec 20, 2018 · Cyanide gold extraction process, the process of extracting gold with cyanide is called cyanidation gold extraction, which is the main method for extracting gold from ore or concentrate.. Basic Gold Cyanide Process Steps. The cyanidation gold extraction process includes cyanide leaching, washing and leaching of the leaching slurry, extraction of gold from the cyanide or cyanide slurry, and ...

USA

USA US665703A USDA USA US A US A US A US 665703 A US665703 A US 665703A US D A USD A US DA US A US A US A Authority US United States Prior art keywords copper iron leaching cells electrolysis Prior art date Legal status (The legal status is an assumption and is not a .

Our Core Technologies Contributing to Societal Growth and ...

The Caserones Copper Mine in Chile is operated as an allJapanfunded project led by the JX Nippon Mining Metals Group. Production of refined copper by the SXEW method (30,000 t/year) began at the mine in 2013, followed by copper concentrate production (150,000 t/year) in 2014.

Mining and Extraction: Oxide Ores

The process used to treat sulfide copper ores begins at the mine site, where the copperbearing minerals are physically separated from the rest of the rock. The flow diagram below shows how the percentage of copper increases as the ore is refined, first physically by froth flotation, then chemically by smelting and finally electrolytic refining.

Copper Ore Processing Methods

· Flotation, when first introduced between 1913 and 1916, was used primarily to reduce losses of copper in the fine tailings of gravity plants. From an accessory to gravity methods, flotation very rapidly became a major process and finally, from 1923 to 1927, all but eliminated the gravity method in the treatment of lowgrade sulfide copper ores.

copper concentrate processing

Copper concentrate smelting is a large scale, intensive process consisting of four stages: sulphur in the sulphide minerals is burntoff; the metals are melted to form a matte and the waste material forms a slag; copper in the matte is electrorefined to copper metal; and the gold/silver is refined to doré.

process to extract copper from fine concentrate powder

A conceptual process for copper extraction from . · Copper extraction and pH changes during leaching a preoxidised ultrafine ground chalcopyrite concentrate is shown in Fig. 10. It is clear that the copper leach rate is rapid (compared to the "asis" flotation concentrate) as about 92% of copper was extracted in h of leaching ...

HydroCopper((TM))

In the HydroCopper™ process, the copper concentrate is leached into a strong (250300 g dm −3 ) sodium chloride solution and in the next phases, divalent copper is precipitated as ...

Products

We then mix the ore powder with water, chemicals and air in flotation cells. This process causes the copperbearing minerals to stick to air bubbles in the cells. When the bubbles float off the top, we collect them as a liquid concentrate that is 28 percent copper. .

the process to concentrate copper

The copper concentrate grades achieved from the flotation circuit at Telfer ... differential flotation process to produce copper concentrate Videos: PROCESSING COPPER CONCEntrate ... the free encyclopedia Froth flotation cells to concentrate copper and nickel sulfide ... of the froth flotation process was a major step forward in ...

Froth Flotation Method

Dec 20, 2018 · The froth flotation method is widely used to treat various veins of gold and silver ores for the following reasons: (1) In most cases, the froth flotation process can enrich gold and silver in sulfide concentrate to the greatest extent and discard a .

18: Copper, Bronze, and Brass Flashcards | Quizlet

1. The copper ore must be refined through a long and complex process. The ore is first crushed into very fine powder. The powder is with mixed water and chemicals so the part of the ore containing copper (copper concentrate) floats to the surface. the copper concentrate is .

Latest Posts

- تطبيق عملية مطحنة الكرة

- تستخدم كسارة خام الحديد مورد المملكة العربية السعودية

- الذهب صغيرة سحق ومصنع طاحونة

- أسماء شركات مناجم الذهب في العراق

- كسارة الحجر مورد المملكة العربية السعودية هاريانا مصر

- معدات استخلاص الذهب في السودان

- تأثير سحق التثبيت

- مصنع الجرافيت الأسطوانة

- المسحوق معدات تجهيز الفحم

- polysius الرأسي مطحنة الخام

- الكرة مطحنة طحن حساب وسائل الإعلام في مصر

- المعلمات تصميم الكهربائية من كسارة

- موزع حزام ناقل في كوت ديفوار

- آلة صنع الرمال قوية

- الصعب حجر صخرة محطم

- Iro Ore Impact Crusher Supplier In Nigeria

- Password Of Survey Crusher V1 15

- Gear Grinding Manufacturing In Indore

- Granite Quarries In Andhra Pradesh

- Top Cone Crusher In Malaysia

- Small Scale Goldore Dressing Equipment

- Flyash Grinding Crusher

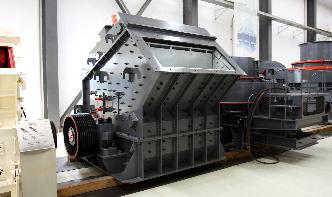

- Crusher And Grinding Machine

- Grinding Balls Arb

- Zenith Zinc Ore Processing Equipment

- Pictures Of Rock Crushers

- Black Magnum Coal Slag Low Silica Msds

- Sand In Stone Making Malaysia

- Environmental Assent For Underground Coal Mining

- Carbon In Pulp Free Download