Roller Mill Body M 5 Design

Size reduction

The design applied here is mainly a ball mill with an agitator, the movement of the agitator making the beads move and impact or friction the particles to be milled. Design using a loose reduction media can be found, mainly in long horizontal mills but other designs, more efficient are actually using a compact vertical bead bed, agitated.

Alignment Of Rotating Kiln Crushing Plant Grinding Mill

Cement Raw Mill Fan Alignment. The ball mill is traditionally the basic system used for the grinding of raw material, clinker and additives in a cement plant, as well as a wide range of minerals. Prices / Quote. Cement Factory Rotary Kiln Rotating Mechanism Xsm. Cement Factory Rotary Kiln Rotating Mechanism.

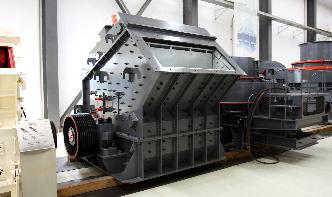

Difference Between Hammer Mill And Crusher

Difference Between Pulveriser And Jaw Crusher. Difference between hammer mill and pulverizer difference between pulverizer and crusher hot products used for portable concrete conveyor for rent scm ultrafine mill cs cone crusher lm vertical mill mtw milling machine vibrating feeder pfw impact crusher thermal power plant way2science a thermal power station is a power plant in which the prime.

Ball Mill Working Principle And Main Parts

Ball Mill Working Principle. To be chosen according to the grinding material, material is composed of a ball mill feed end of the hollow shaft is arranged in the tube body, when the ball mill cylinder rotation time, grinding body due to inertia and centrifugal force, the effects of friction, making it attached to the cylinder liner on the cylinder body away, when taken to the height of a ...

Coal pulverisation with vertical roller mills | Engineer Live

Feb 01, 2013 · Coal pulveriser design. In general, coal pulverisers are designed to achieve the maximum rated capacity grinding a design coal with a grindability of 55 HGI and 812 per cent moisture and achieving a discharge fineness of 70 per cent passing a 200 mesh screen (74 micron) and per cent passing a 50 mesh screen.

Monster Mill MM3 Grain Mill Complete Packages | MoreBeer

These Packages come complete with a Base, 3 Roller Monster Mill Body, and a Hopper. Choose whether to include the Hopper Extension, which upgrades Hopper capacity to a huge 39 lb! Features: Three sixinch steel rollers form two gaps, a preliminary fixed gap of .

Feed manufacturing grinding

May 07, 2016 · ROLLER MILL OPERATION GENERAL DESIGN 1) A Delivery Device To supply a constant and uniform amount of the material 2) Pair Of Rolls Mounted horizontally in rigid frame 3) One roll Fixed in position And Other is Moveable closer to or further from fixed roll 4) Rolls counter rotate either at same speed or one may faster 5) Roll surface may be ...

mechanical engineering: Types of rolling mills

2: Three high rolling mill: It consists of a roll stand with three parallel rolls one above the other. Adjacent rolls rotates in opposite direction. So that the material may be passed between the top and the middle roll in one direction and the bottom and middle rolls in opposite one. In three high rolling mills the work piece is rolled on both ...

ROLLER MILL BUILD STARTING

Jun 23, 2010 · Hello John, That was a beautifully documented build. I am currently running a Matt Whitmas built mill that I love. 5"dia. rolls, 12"wide, 5hp hydraulics with forward/reverse. But.. I'm working on a project (sanmai construction) that will require a stepped transition from bolster to distal tapered sword length blade.

ProductsZeolite roller mill,Raymond roller mill,Three ...

Products. China Three Roller Grinding Mill: Shanghai Clirik Machinery Co., Ltd is a large professional manufacturer of China Three Roller Grinding Clirik China Three Roller Grinding Mill have five models: YGM7815,YGM8314,YGM9517,YGM4121,MTM16. The main body of Raymond mill drives the central shaft through the transmission.

Metal Shaping Tools | Sheet Metal Working Tools | Baileigh ...

Roll Bender Tooling. RM5 Tooling; RM7 Tooling; RM10 Tooling; RM20 Tooling; RM40 Tooling; RM55 Tooling; RH45 Tooling; RH55 Tooling ; Tube Bending Accessories; Sheet Metal Brakes, Rolls Shears. Combination Machines; Sheet Metal Brakes. Straight Sheet Metal Brakes; Box Pan Sheet Metal Brakes; Hydraulic Sheet Metal Brakes; Magnetic Sheet Metal Brakes; Slip Plate Rolls. Slip .

Otherstock Online Auctions In Minnesota

LOT OF (5) UNITS 24" general purpose tire iron features a curved spoon end and a curved offset hook end to easily separate tire beads. Use it with a tire machine or manually. The tire iron is made from rugged forged steel with a chrome plate finish. Rugged forged steel with chrome plate fi...

Gluten Washer 6000

Gluten Washer Bastak brand and its model is 6000. It is used to determine the amount of wet gluten in wheat and flour samples by extracting wet amount of wet gluten in 2 samples can be determined device is fully automatic. The

Ball Mill Liners Material Selection And Appliion

Ball Mill Liners Material Selection And Appliion. The ball mill liners and grinding media are the largest consumption of wearresistant iron and steel parts with an annual consumption of 2 million tons in China. With the development of China's economic construction, the demand for cement is increasing year by year, and the consumption of ...

Pin mill type contrarotor "C30 – C60" – Cimma Ing ...

Mill's body in cast alloy (welded STAINLESS STEEL on demand) Pin rotor in hardened steel or stainless steel (cryogenic appliions) The CONTRAROTOR C60 type is developed with heavy duty design for minerals and chemicals, with higher capacity 13 t/h.

Table of design properties for metric steel bolts M5 to ...

· The width of the hexagon nuts across flats s is specified in ISO 8982 Table for bolt sizes M5 to M39. Hole diameter. The design shear resistance of bolts F v,Rd as given in EN199318 Table is only valid when the bolt is used in holes with nominal clearance not exceeding the values given in the standard EN 10902 'Requirements for the execution of steel structures', as specified in ...

Grinding Mill With Support Platform

Whether your plant relies on hammermill, attrition mill, roller mill, cutters or screening techniques, Repete systems provide optimization for all grinding systems controlling feeder speed based on type of ingredient, grinding apparatus and transfer to the next part of the process. Grinding Mill Hoffman Manufacturing . The grinding unit is complete with a pair of 4 grinding plates, which can ...

Blog – Your Portal For all you Online shopping

Aug 06, 2021 · Generally, the grading range is 25% ~ 35%, but the intermediate grading in practical appliion is mostly 28% ~ 32%. LM vertical roller mill steel ball grade ratio under common economic operation: steel ball diameter mm Φ one hundred Φ eighty Φ sixty Φ forty Φ 20 mass / total filling quantity % % % % 22 [.]

Latest Posts

- معدل تحميل كسارة مخروطية

- المستخدمة الرمل النهري معدات التجهيز المملكة العربية السعودية

- آلات ومعدات الطحن

- كسارات حجرية صغيرة مصنعة في السعودية

- يستخدم مخروط محطم أو تأثير محطم

- نباتات مستعملة للبيع في السعودية

- الرسم من الحزام الناقل

- تأجير كسارة خرسانية صغيرة عالية wycombe

- طحن مطحنة الصين السعودية الاتصال

- تستخدم آلة ضخ الرمل للبيع

- تكلفة من كسارات الصخور

- آلة كسارة فكية الحجر

- تكلفة إلمينيت محطة إثراء

- 100 طن في الساعة سعر محطم

- تعديل الأسطوانة كسارة هيدروليكية مصر

- Working Methods In Coal Mines In Uruguay

- Separators For Cement Grinding Fabricators

- Crusher High Pressure Powder Mill

- Crusher Gold Coal

- Use From In Pit Crusher

- Pneumatic Crusher Best

- Jacques Jaw Crushers Pully And Belts

- Designing A Ball Mill

- Laboratory Cement Ball Mill

- Terrazzo Grinding Machine Manufactures

- Conveyor Belt Drive Roller Malaysia

- Fine Silica Sand Grinder In The Philippines

- Haudraulic Pressure Cone Crusher

- What Is The Process Of Mining Rose Quartz

- Ore Processing Of Tantalite With Magentic Separation