Steps To Replace A Crusher Jaw In A Plant

Design Calculation Of The Jaw Crusher Pdf

Design Of A Crushing System That Improves The. Has to follow these three steps crusher selection crusher layout and process design 24 crushers a crusher is a tool or machine that is used to reduce the size of a large solid particle to a smaller solid particle the ore can have a size of up to 400mm there are many types of crushers but the major ones are the jaw gyratory and the cone crusher

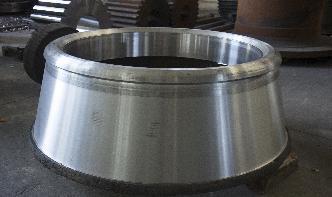

Replacement parts for jaw crushers

Replacement parts for jaw crushers Products. As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including, Replacement parts for jaw crushers, quarry, aggregate, and different kinds of minerals.

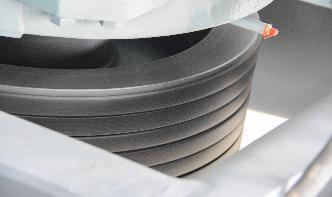

Cone Crusher Explained

Jaw Crushers; Cone Crushers; Typically, the initial crushing stage is completed using either gyratory crushers or jaw crushers. It is often the case that there will be only one crusher installed, and this will be referred to as the primary crusher. Cone crushers are more often used for 2nd, 3rd 4th stage crushing steps (although not always).

crusher eccentric crushers

mesin jaw crusher makayama tahun 2015 ball crusher for line australia crusher supplies gold jaw crusher historic crusher aggregate india hard rock crusher mill 10 t h size of the gyratory crusher jaw crusher cap 500 tph stone dolomite crusher plant membuat rakitan rangka stone ... Jaw crushers are used as primary crushers, or the first step in ...

Cedarapids JW55 Jaw Crusher

Jaw Crusher. The JW Series is engineered for portability and ease of use. The rugged design delivers the reliability you can expect from Cedarapids. They feature a hydraulically actuated wedge system that allows variable closed sidesetting adjustments to be made quickly and easily. Designed to suit track, mobile or static plant installations ...

Mobile crushers – Rockster North America

Jan 14, 2021 · "If I had purchased a portable jaw plant for our type of appliion, in order to create a consistent size material, I would have also had to purchase a portable screening plant to work alongside the jaw crusher," he said. "A jaw crusher would have made an initial break of the processed material into roughly the size of 6inch minus, much ...

Granite Stone Crusher in NigeriaSBM Industrial Technology ...

Aug 18, 2021 · Granite Jaw Crusher. Jaw crusher is kind of granite crusher which performs as the primary crusher, the feeding size of which can reach 1000mm, and also the final size of granite dust may be adjusted from 10100 mm. Jaw crusher has super wear resistance and impact resistance, very flexible adaptability, more safe and reliable operation process, ultralow failure rate, and can give full .

Best Practices for Crushing, Screening RAP | AsphaltPro ...

When it comes to production capacities of impact crushers compared to jaw and cone crushers for the crushing and screening of RAP, Ryan Freeman, the general manager at Rason Materials, shared his experience. "Rason operates five asphalt plants and four crushing operations, all on Long Island, New York," Freeman said.

Jaw crusher, Jaw crushing plant

jaw crusher. UJ310. Capacity: 0 t/h 270 t/h. The UJ310 wheelmounted crushing plant is a comprehensive system comprised of all the process steps needed in crushing operations. The system is designed for easy transport between sites, and can be easily set ...

IROCK Crushers | OEM Crushing Screening Parts

Low Cost Financing Options on Crushing Screening Plants. Up to 72 Months .9%* and up to 84 Months %* ... Jaw Crusher. Mobile. TJ2440 – Mobile Jaw Crusher TJ2745 – Mobile Jaw Crusher ... You can trust that you'll connect with a knowledgeable human whose job is to pull and ship the wear and replacement parts you need from our fully ...

Portable Primary Impact Crushers

Portable Primary Impact Crushers are wheelmounted rock crushing machines, engineered for primary crushing appliions. These plants are extremely versatile and economical units and have proven their effectiveness in a host of missions like crushing soft and mediumhard materials such as limestone, low abrasive rocks, for quarrying, cement industry, concrete and asphalt recycling and are the ...

Stationary Crushing Plant

The crushing is generally divided into three steps: 1. The first step of crushing: the input size 1500 ~ 500mm, the output size 400 ~ 125mm ;. 2. The second step of crushing: the input size 400 ~ 125mm, the output size 100 ~ 50mm ;. 3. The third step of crushing: the input size 100 ~ 50mm, the output size 25 ~ 5mm.

Steps for Removing the Jaw Plate of the Jaw Crusher ...

1. Fill the lower ore bin with ores. Before the crusher stops, remove unstable ores at the ore outlet after the heavy plate feeder stops to prevent them from falling during construction.. 2. Stop the crusher after breaking the mine, and clean the slag around the wedge block, wedge fixing bolt and jaw plate hoisting hole with the sweeper.

PQ University Lesson 7 Crushing Secondary Breaking ...

Sep 02, 2019 · The major wear part for a mobile crushing plant is the crusher itself. In a jaw crusher, the major wear parts are very limited – only a fixed jaw and a swing jaw, and two or four side or cheek plates. An impact crusher, on the other hand, has a lot more wear items.

primary jaw crushers Archives

Then, when it comes to comminution, a crushing (including primary jaw crushers) and screening portfolio, plus smaller milling options and expertise in high pressure grinding rolls (HPGRs) through the globally renowned Polysius business, is bolted onto FL's own crushing and grinding (including vertical roll milling technology) portfolio.

4 Types of Stone Crushers' Maintenance and Efficient ...

Aug 28, 2021 · 4 Types of Stone Crushers' Maintenance and Efficient Improvement. There are different types of stone crushers in mining industry such as jaw crusher, cone crusher, impact crusher, and sand making machine. This article will tell you how to maintain the 4 types of rock crushers and how to efficicently improve their performance. Many stone crusher ...

Differences Between Jaw Crusher and Hammer Crusher, How ...

2. Crushed material. Jaw crusher can crush all kinds of hard and soft materials, the compressive strength is between 300350mpa. Such as granite, quartz, diabase, river pebbles, iron ore, etc. Hammer crusher crush the materials that hardness is not high. The compressive strength is .

Quarry, Mine and Mobile Plant Maintenance

Crusher Maintenance. NCCM provides specialised maintenance and repair services for jaw crushers, gyratory, cone, impact and compound crushers. We believe performing regularly scheduled maintenance on your assets is one of the most critical steps in ensuring the day to day reliability and optimum.

Portable Crusher Plant

Crusher plant consist of vibrating feeders, jaw crushers, cone crushers, impact crushers, vibrating screens, belt conveyor and electric control panel etc. Crusher Plant designed throughput generally is 50600 t/h. Sand washing machine and other machines can be added to this line to meet the various customers' requirements.

Bearing Crusher Changing

Changing Jaw On A Crusher. Changing bearings on a jaw crusherhe main bearing of large jaw crusher is used mostly to open sliding bearing, bearing liner is mostly wing jaws parker crusher crusher south africaat material is used in the manufacture of the jaw hanging jaws on a jaw crusher sand crushing plant manufacturer hat is manufactured.

Latest Posts

- توازن الكتلة في مصنع الاسمنت

- كسارة حجر برومان السعودية

- محطات تصنيع خط عملية مخطط

- كسارة الحجارة في ماهاراشترا

- عملية تعدين الرمال في كوالالمبور

- سعر كسارة الفك X

- كسارات المطرقة ذات المحور الرأسي

- كسارة حجارة بسيطة في الجزائر

- الاستشاريين تصميم مخروط محطم المملكة العربية السعودية

- بكرات بديلة لمطحنة الأسطوانة

- كسارة صناعة التعدين السعودية

- طبل فاصل كهروضوئي طبل

- المجلات الحجر كسارة في مصر

- بيع مصنع محطم المحمولة

- ارتفاع سعر مطحنة الأسطوانة

- Rock Crusher Equipment Machine

- Crusher Panama 35 9

- Jaw Crusher Philippines Sale

- Iron Ore Crusher Equipment In Malaysia

- Mobile Limestone Cone Crusher For Sale In Malaysia

- Turnkey Crusher Crushingturnkey Crusher Gt

- Quarry Equipments In Seconds

- What Are The Effects Of Vertical Mill Power Consumption And Output

- Oilseed Crush Industry Austria

- Double Toggle Stone Crusher

- Grinder Machine Working Principle

- Granite And Mining Forms

- Sbm Mineral Penghancur Model Vertical Shaft Impactor

- Australia Jaw Manufacturers

- Largest Coal Mines World