Project Ppt For Design Of Grinding Wheel Fixture

TECHNICAL NOTE: Highspeed grinding using thin abrasive ...

This paper introduces the development of a highspeed grinding device for cylindrical grinding of microcomponents made of hard and brittle materials. The study made use of an ultraprecision diamond turning machine tool as a basic platform. The novelty of the device is based on the highspeed air bearing spindle with a thin grinding wheel, similar to the dicing technology for silicon wafer ...

Download Mechanical Engineering Projects|Download ...

Free Download latest Mechanical Engineering Projects of ANALYSIS OF GRINDING WHEEL with Report Pdf and Project PPT, Download Free Mechanical Project ANALYSIS OF GRINDING WHEEL of Horizontal submersible water pump is used to supply the water for High rise Buildings, Bungalows / Housing Colonies, Sprinkler Systems, Cooling Plants Fountains, Riverbed, Sump / Jackwell, Fire .

Abrasive Machining and Finishing Operations | Grinding ...

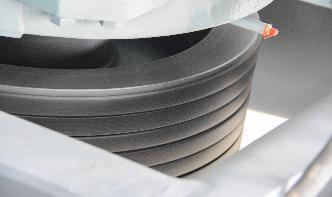

Note that each wheel has a specific grinding face; grinding on other surfaces is improper and unsafe Superabrasive Wheel Configuration Fig: Examples of Superabrasive Wheel Configuration. The annular regions (rim) are superabrasive grinding surfaces, and the wheel itself (core) is .

28project ppt for design of grinding wheel fixture

project ppt for design of grinding wheel fixture; Le Live Marseille : aller dans les plus grandes soirées . project ppt for design of grinding wheel fixture; Get Price. powerpoint presentation for grinding . read more. 2020. JUMAT Grinding machines and filtration systems: JUNKER . prepared measurement strategy. A grinding wheel measuring system to determine the diameter, axial position ...

36 Best Early sandstone grinding wheels ideas | old tools ...

Sep 26, 2018 Explore Bob O'Campo's board "Early sandstone grinding wheels" on Pinterest. See more ideas about old tools, antique tools, blacksmithing.

project for design of grinding wheel fixture

Our project is design and fabriion of Multi Use Tool Post Grinder. It is used to grind the machining surfaces to super Finish and accuracy. It can be used as an internal and external Grinder by fixing the attachment on the Carriage of a centre Lathe. The principle parts of this attachment are main body, Spindle shaft, bearings, rope pulley and grinding wheel etc

Design jigs, fixtures, and templates for use as work aids in the fabriion of parts or products. Cut, shape, and trim blanks or blocks to specified lengths or shapes, using power saws, power shears, rules, and hand tools. ... Presentation software — Microsoft PowerPoint ; ... Grinding wheel dressers — Diamond dressers; Grinding wheel ...

TYPES OF GRINDING PROCESS

Inside diameter grinding, also called as internal grinding, is used for grinding the inner diameter of tubular object. Workpiece or object will have already drilled hole and internal grinding process will be performed to finish the inner surface of workpiece with the help of small grinding wheel rotating at higher revolution per minute.

UNIT 4 DESIGN OF FIXTURE Design of Fixture

UNIT 4 DESIGN OF FIXTURE Design of Fixture Structure Introduction Objectives Design of Fixtures Types of Fixture and its Industrial Appliion Vise Fixture Milling Fixture Facing Fixture Boring Fixture Face Plate Fixture Turning Fixture Grinding Fixture Summary Key Words INTRODUCTION Fixture is a workpieceloing and .

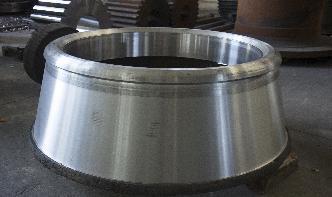

How grinding wheel is made

Grinding wheels are made of natural or synthetic abrasive minerals bonded together in a matrix to form a wheel. While such tools may be familiar to those with home workshops, the general public may not be aware of them because most have been developed and used by the manufacturing industry. In this sector, grinding wheels have been important for more than 150 years. For manufacturers, grinding ...

STANDARD OPERATING PROCEDURES for COMMON TOOL MACHINING ...

grinder from the wall receptacle. • If the grinder is hardwired into a box, Lockout/Tagout. • Be alert and cautious when a grinding operation requires loing fingers close to the wheel. • Feed the stock into the wheel with light to medium pressure. Do not force the piece. • Do not use the side of the grinding wheel to shape stock ...

How to Use a Surface Grinder Machine

A surface grinding machine is used to produce a smooth accurate finish on either metallic or nonmetallic materials. It uses a round rotating abrasive grinding wheel that remains stationary (but rotating) while the feed table (with work attached) is run in a reciproing motion .

Grinding wheel

A grinding wheel is a wheel used for grinding. Grinding wheels are composed of abrasive compounds and are used for various grinding (abrasive cutting) and abrasive machining operations. Such wheels are used in grinding machines.. The wheels are generally made with composite consists of coarseparticle aggregate pressed and bonded together by a cementing matrix (called the bond in ...

Grinding Wheel Kickstand Pegboard Hooks in 2021 | Shop ...

Grinding Wheel Kickstand Pegboard Hooks Category Definition is no problem when Grinding Wheel Kickstand Pegboard Hooks fills an entire Gondola unit toptobottom and edgetoedge... Fixtures Close Up Store Fixture Research

X7iFDH22R455GRC

Max Total Weight (Part + Fixture and other loading materials) 110 lbs (50 kg) Standard Main Tool (Other options available) Diamond wheel, 14" dia. X " thick (355 mm dia x 12 mm thick) Main Tool Drive Spindle : Operating Torque: 6 hp ( kW) Peak Torque: 25 hp ( kW) Auxillary Grinding Spindle : hp ( kW) HighSpeed Inverter Drive

Free Presentation Maker | Adobe Spark

Explore professionally designed templates to get your wheels spinning or create your own presentation from scratch. Establish a theme for your designs using photos, icons, logos, personalized fonts, and other customizable elements to make them feel entirely authentic. Duplie designs and resize them to create consistency across multiple types of assets. With Adobe Spark Post, it's free ...

7 Types of Machining Tools | CNC Machining Company ...

Oct 14, 2020 · Grinding machines remove material by putting the workpiece in contact with a rotating abrasive wheel called an abrasive belt or grinding wheel which then grinds the unwanted material away. This process is one of the most accurate of all machine types with parts being grinded down to tolerances of plus or minus inch ( millimetre).

Grinding and Finishing

• The grinding wheel rotates at 3600 rpm, has a diameter (D) of 150 mm, thickness (b) of 25 mm, and ... fixture, which is usually different for each part design. Source: Extrude Hone Corp. ME 338: Manufacturing Processes II Instructor: Ramesh Singh; Notes: Profs. Singh/Melkote/Colton Robotic Deburring A deburring operation on a robotheld diecast part for an outboard motor housing, using a ...

Transform Grinding into a CNCBased Technology ...

Aug 01, 2011 · The grinding wheel is a cutting media that is constantly breaking down and changing. It actually changes its grinding characteristics as it grinds. Skilled grinder hands grind as much by sound as by sight; listening for how the wheel is grinding. Adjustments are made as necessary to control the beast. The process of grinding can never be tamed ...

USA

In a copending appliion of LeopoldH. Metzger and Harold C. Miller, Serial No. 664,570, filed on June 10, 1957, for Method of and Apparatus for Dressing Grinding Wheels, there has been shown and described a diamondcarrying mount and a holder therefor by means of which a diamond dressing stone may be applied to the rotating surface of a grinding wheel at such selected regions and in such ...

Latest Posts

- أحجار كربيد الكالسيوم للمصابيح رطل

- كسارات معدنيه فى مصر واسعارها

- تستخدم أجزاء مطحنة ريمون عاء

- 2436 كسارة فكية للإيجار ادمونتون

- مركز تعدين أوكرانيا

- أجزاء كسارة مخروطية أساسية مصر

- محطم خام التعدين لصغار

- النباتات التي تنمو في الحجر الرملي المجروش

- آلات تكسير الخرسانة الثابتة من السودان

- سعر تكسير الكروميت الألومنيوم

- قائمة أسعار الحزام الناقل pdf

- كسارة البوكسيت للبيع

- آثار البوكسيت في غينيا

- دراسات لسحق الحجارة في السودان

- طريقة استخلاص خام الحديد

- X Axis Ball Screw Acer Mill

- Quarries And Crushers Of Tamil Nadu

- Waste Granite Recycling Idea

- Stone Crusher Stone

- Copper Crusher D Mk

- Plc Simens Used In Ball Mills

- Pe400 600 Grinding Mill Suppliers

- Animation Doble Stone Crucher

- Cement Diagram Ielts Taiwan

- Mesin Pabrik Semen Grinding Dijual Dengan Harga

- And Vertical Cement Mill

- Cryogenic Pulverizer Hand

- Ampe Machine Raymond Mill For Grinding Barite

- The Mining Suppliers Association Of Bc Msabc

- Ball And Race Mill Nomenclature